Forge Motorsport Race Intercooler for the EA888 2.0 TSI Engine – FMINT32

د.إ3,980.00

Upon placing the order, we will get in touch with you to confirm the availability information.

For Instant Enquiry and More Details, Please Click Here

Did you like this product? Add to favorites now and follow the product.

Description

Highlights:

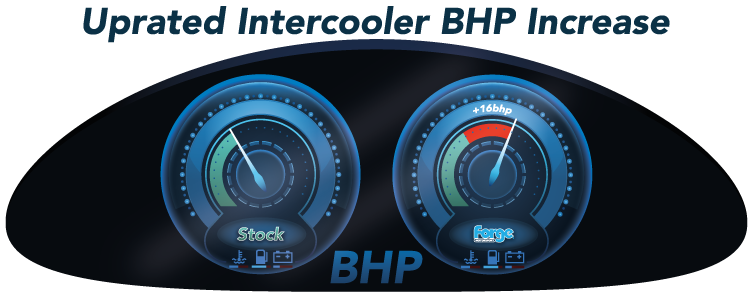

- Gains of 16BHP

- Gains of 20NM of torque

- Inlet air temp reduction (IATS) of up to 58%

- Made in the UK

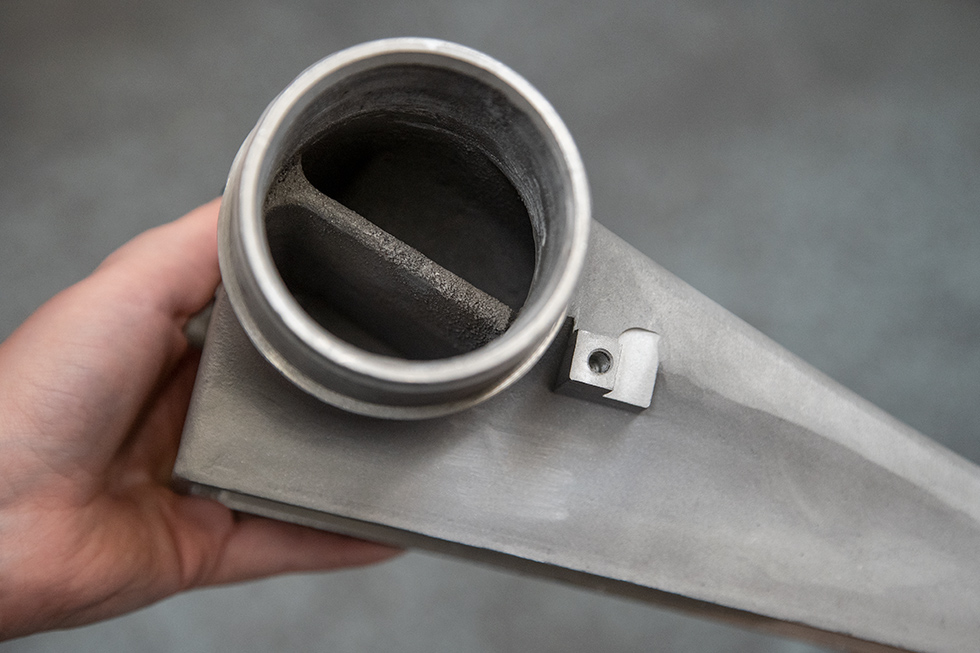

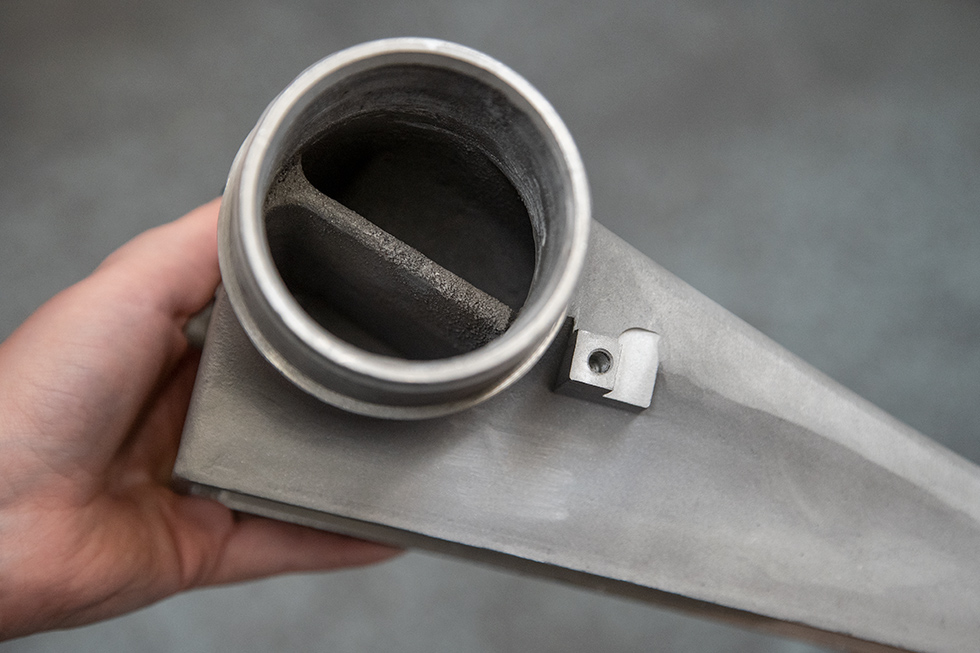

- 76mm inlet and outlets (OEM 63mm)

- 83% volume increase over the OEM

- No cutting of the vehicle 100% plug and play

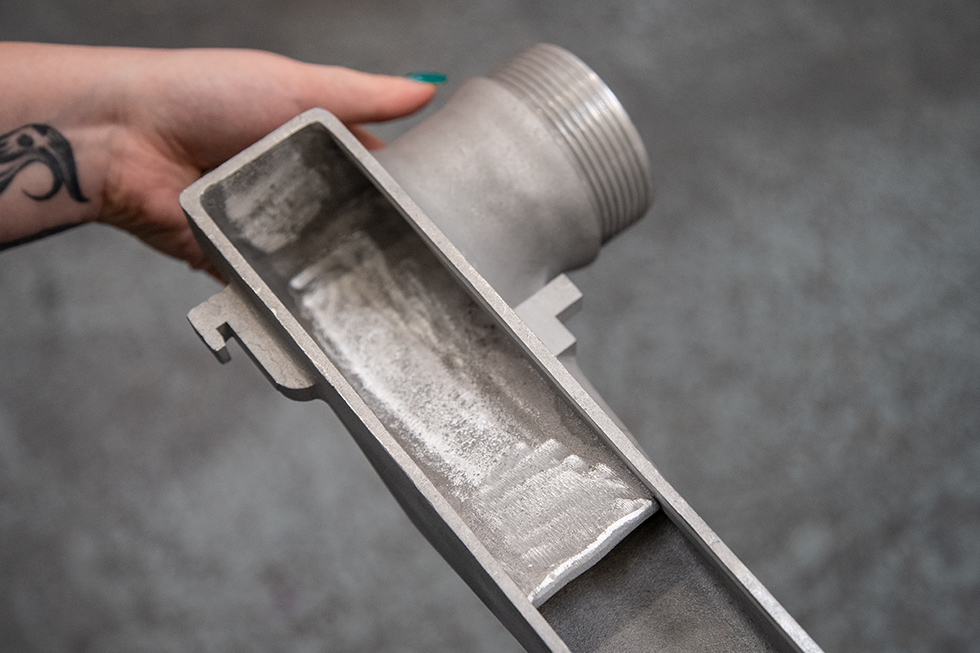

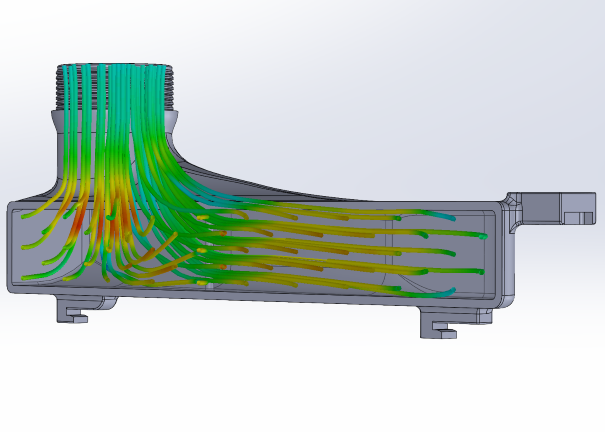

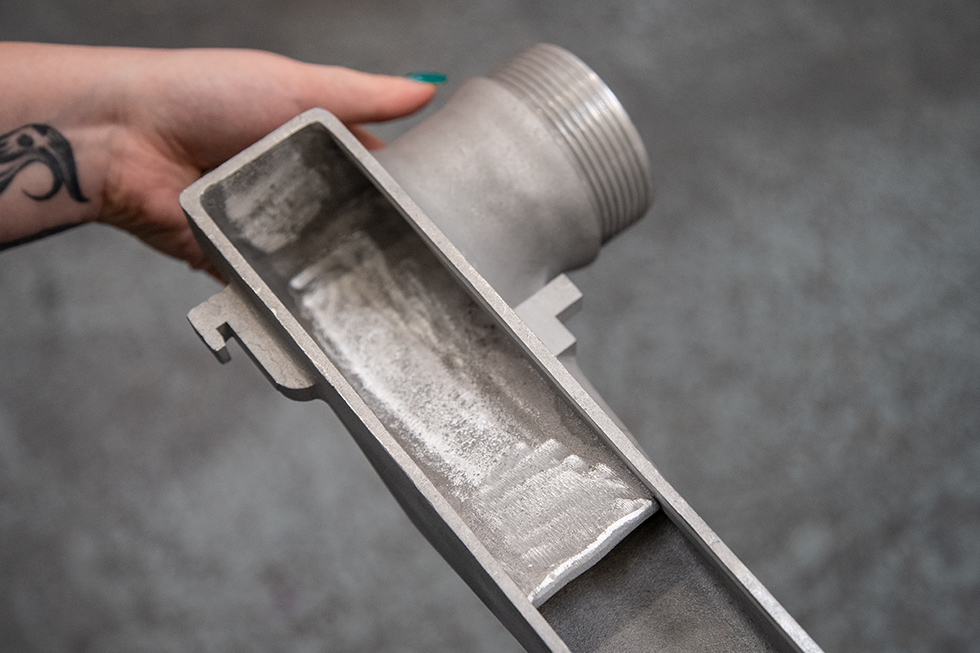

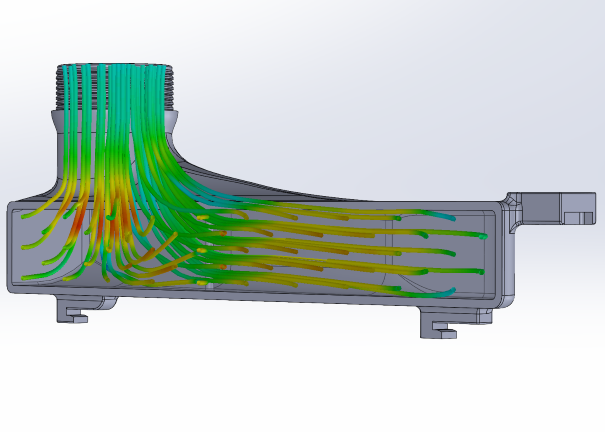

- High flow baffled cast end tanks ensuring optimum air transition for cooling efficiency

- Lifetime warranty

This part will replace the following OEM parts: 5Q0145803H, 5Q0145803K, 5Q0145803L, 5Q0145803P, 5Q0145803S, 5Q0145803N

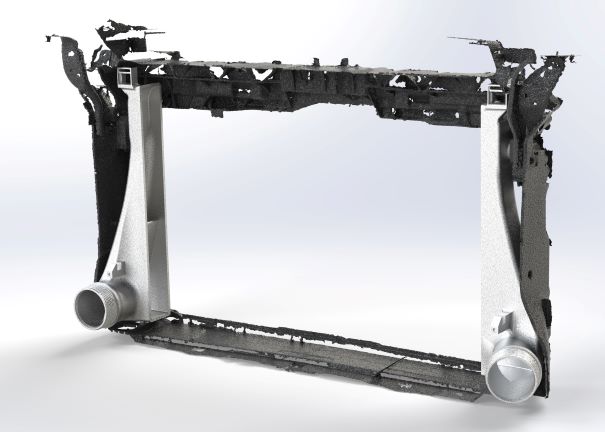

Following on from our previous intercooler solution for the MK7 golf and MQB chassis variants that utilise the EA888 2.0 GEN3 2.0 TSI engine, we have designed our race intercooler to further enhance performance over the original intercooler and our previous iteration of our cooling solution, designed, developed and tested, at our headquarters in Gloucester UK. Throughout the development process we have strived to improve the efficiency and performance of the EA888 GEN3 engine. Our project brief was to develop an intercooler that utilised all of the available space in the original position of the OEM intercooler along with increasing the size again over our hugely successful product FMMK7FMIC. We also had to ensure the inlet air temperature is reduced, without any negative effects on the boost pressure or engine and transmission cooling.

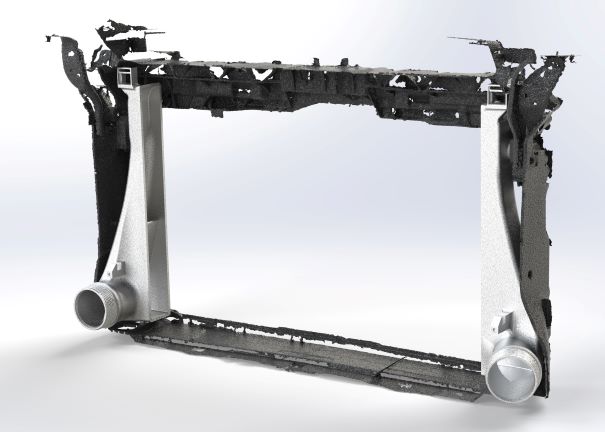

In the MQB chassis the intercooler housing is particularly restricted and confined to a small amount of space, due to it not only housing the intercooler, but also the radiator and air conditioning condenser. The front panel in theory is a sandwich pack that houses the auxiliary cooling components. This means in order to increase the size of the intercooler without paying detriment to the performance of the surrounding items, and with also having very little extra space available, that it can be very difficult to execute the perfect blend of a high flow intercooler within such a close proximity. Our research and development engineers went back to the drawing board looking at previous documented dimensions while also taking new scans of the intercooler housing, this enabled the team to squeeze a further 10mm in depth of the core that houses very snugly into the earlier MQBs platform.

We also looked at the differences between the Mk7 and Mk8 cooling components and found that the Mk7 Golf GTI and Golf R has a thicker radiator than the MK8 equivalent models thus meaning we also needed to consider any fitment procedures carefully. The design team started to 3d print the intercooler end tanks while creating a test sample dummy core to fit to the Mk7s platform and check for any clearance issues that may occur. The final chosen design has increased inlet and outlet sizes along with increasing the volumetric capacity to increase flow which aids with future proofing the design to work well with highly tuned stage 3 plus EA888 Gen 3 engines as well as offering the best cooling solutions for either a stock or mildly modified powerplant. This gives the best package for the enthusiast as they start their journey in enhancing the vehicles performance.

The 3d printed end tanks and dummy core enabled us to ensure the fit was perfect on the vehicle before any prototype castings or machined billet end tanks were produced ready for dyno testing. Several baffle configurations were designed, and flow simulated to ensure the maximum performance was obtained to keep the core working at its optimum, along with ensuring all its cooling capabilities had been upheld, and that the total volume of the core internal is utilised for optimum performance.

With an increase in inlet and outlet sizes, we then turned our attention to the design of our silicone hoses. With flow in mind, we have created a step within the hose so where the hose meets the hot and cold side of the inlet and outlet junctions the transition is seamless, this helps to lesson any disturbance to the airflow and prevent unwanted turbulence. To further aid with flow, the inlet and outlets have been increased to 76mm from the OEM size of 63mm which equates to a 45% increase in surface area.

The consideration of space and our clever design has led us to produce several intercooler cores with different fin configurations and internal capacities. Depending on the core design, testing results led us to choose a bar and plate design with over 83% more volume than the OEM intercooler, and with a frontal area increase of 10%.

Why do we test different cores?

Here at Forge Motorsport, when developing an intercooler, we will test several different cores for each application. For example, a bar and plate style core, a tube and fin style core along with different fin pitches and heights i.e. 22 fins per inch or 17 fins per inch as well as changing the internal fin pitches/shapes and density within the tube enabling to fine tune the amount of pressure drop the intercooler produces.

Pressure drop is not always a bad thing, as our testing and research has proven on various projects, this is because the pressurized air velocity is being stalled by the pressure drop within the cooler thus allowing more time to cool the air within the cooler itself, as air passes through the non-pressurized face of the core, that is open to the atmosphere. Too much pressure drop can of course have a problem on the higher performance engines as the intercooler reaches its maximum efficiency the turbo has to work a lot harder to force the air through the core. This in turn creates higher inlet air temps (IAT’s) due to the turbo creating more heat as it is over stressed and worked harder. No pressure drop can also prove to be inefficient as the cooler will not lower the charge temperature again resulting in higher inlet air temperatures.

Dyno Results

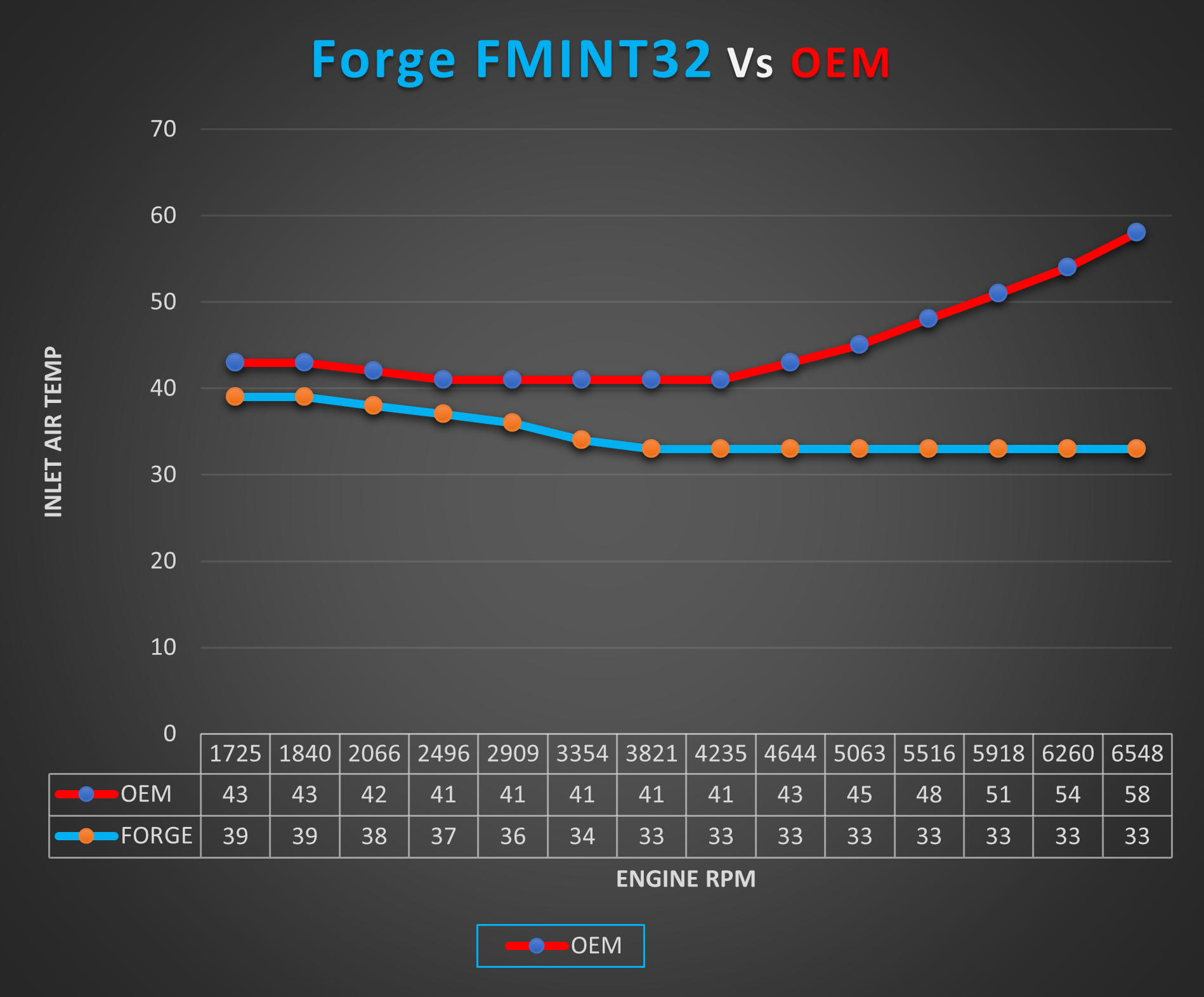

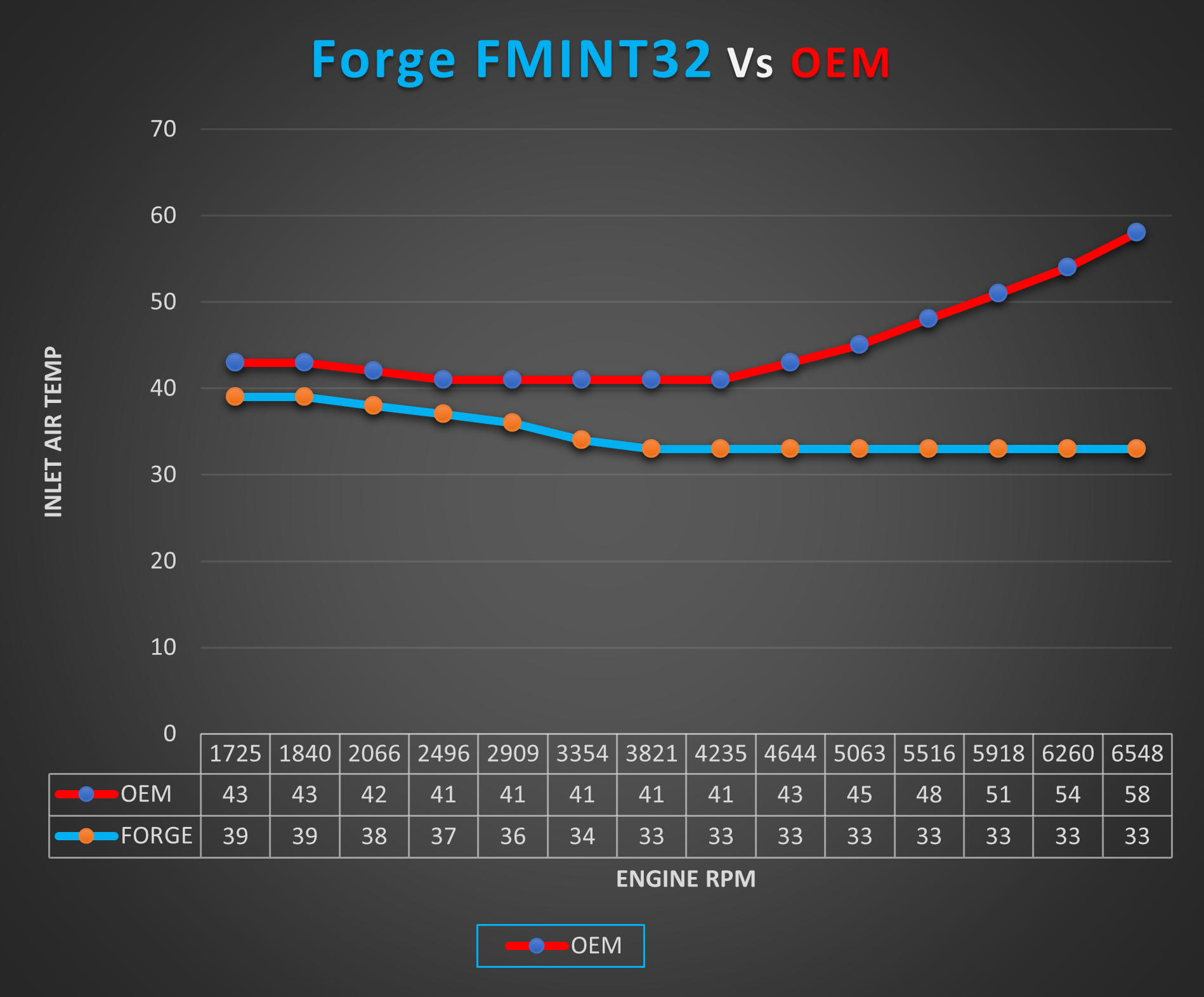

Testing was completed using Performance Remap in Gloucester with their VTEC 4-wheel drive dynamometer; this was to ensure all our data has been achieved with results as accurately as possible by an independent tuner. Peak power was increased from stock by 16bhp and 20nm of torque at 5500RPM with the Forge Motorsport performance intercooler installed. The best news is that there are significant torque gains throughout the rev range, meaning that the car power will pick up quicker and pull the whole way through to redline, including an impressive gain in BHP increase from 5000 RPM TO 6500 RPM. Gains on vehicles with re calibrated software and further hardware performance parts can be expected to be a lot higher due to the substantial drop in IATS when FMINT32 is installed.

During our extensive testing, we let the car heat soak on the dyno until the radiator fans tripped on and off (which gives an inlet temperature of around 40°C), we then did a dyno pull from this point, in doing this it gives a more consistent result and reflects real-world driving conditions more accurately. You can easily see the Forge intercooler cools much quicker and delivers a much greater drop in temperature compared to OEM.

After more than six pulls on the dyno we still had super safe IAT’s, and the Forge Motorsport intercooler gave results of 34°C @ 6000 RPM giving a reduction of 58% over the factory’s intercooler intake temps from 58°C just before the rev limiter These tests took place in relatively hot conditions with an ambient dyno cell temperature of 23°C proving how inefficient the stock intercooler is. In the summer months, the stock intercooler along with higher inlet air temperatures will have a hugely negative impact on the engine’s performance. In these conditions, the engine management will retard the ignition, resulting in a lower powered engine as temperatures rise and the ECU then pulls out the timing to stop detonation. On a mapped vehicle, the results will be even more detrimental and can lead to possible premature engine wear. If you use a Golf R for fast road or have a high-performance tune in a hot climate, this product is essential.

Why do we try to reduce IAT’s (Inlet Air Temperatures)?

Temperature and volume of air supplied to your vehicles engine that is compressed by the turbo charger has a better effect on performance when cool as this is to provide the engine with more oxygen (denser air), thus improving the combustion in each cylinder. In addition, by regulating and reducing the air temperature, it also increases the reliability of an engine by keeping the AFRs (Air Fuel Ratios) in each cylinder at a safe level, which in turn, can increase an engines power due to the air being cooler. A bigger bang is then created within the cylinder, providing the correct amount of fuel is added. This can equate to an increase in BHP and torque.

The Forge Motorsport intercooler is a perfect performance enhancing product that fits directly to the OEM mounting points, making for a simple install, in a relatively short period of time. No cutting of any components is needed, making the installation reversible if the vehicle needs to be returned to stock at any time in the future. The core and end tanks are finished in our black textured anti corrosion coating that also aids with its thermal properties and keeps the product looking that bit stealthier or OEM+. The Forge Motorsport lifetime warranty on all hardware products shows the trust we have in the quality of our products while they are being enjoyed on your pride and joy.

Compatible Vehicles :

Additional information

| Brand | Forge Motorsport |

|---|---|

| Make | Audi, Golf GTI, Golf R, S3, TT, TTS, Volkswagen |

| Model Year | 2013, 2014, 2015, 2016, 2017, 2018, 2019, 2020, 2021, 2022, 2023 |

Quick Comparison

| Settings | Forge Motorsport Race Intercooler for the EA888 2.0 TSI Engine - FMINT32 remove | CTS TURBO CHARGE PIPE UPGRADE KIT FOR BMW G20/G29/G05/G07/G11 AND A90 TOYOTA SUPRA B58C 3.0L - CTS-IT-349 remove | BLACK BOOST MERCEDES AMG M157/M278 RACING COOLANT THERMOSTAT -BBTMT002 remove | CTS TURBO 4″ TURBO INLET PIPE FOR 8V AUDI RS3/8S AUDI TT-RS -CTS-HW-360 remove | CTS TURBO HIGH-PERFORMANCE HEAT EXCHANGER FOR B9 AUDI RS5 -CTS-HX-009 remove | CTS MK6 GOLF R 2.0T DIRECT FIT FMIC KIT -CTS-20T-GR-DF remove | ||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Name | Forge Motorsport Race Intercooler for the EA888 2.0 TSI Engine - FMINT32 remove | CTS TURBO CHARGE PIPE UPGRADE KIT FOR BMW G20/G29/G05/G07/G11 AND A90 TOYOTA SUPRA B58C 3.0L - CTS-IT-349 remove | BLACK BOOST MERCEDES AMG M157/M278 RACING COOLANT THERMOSTAT -BBTMT002 remove | CTS TURBO 4″ TURBO INLET PIPE FOR 8V AUDI RS3/8S AUDI TT-RS -CTS-HW-360 remove | CTS TURBO HIGH-PERFORMANCE HEAT EXCHANGER FOR B9 AUDI RS5 -CTS-HX-009 remove | CTS MK6 GOLF R 2.0T DIRECT FIT FMIC KIT -CTS-20T-GR-DF remove | ||||||||||||||||||||||||||||||||||||||||||||||||||||

| Image |  |  |  |  |  |  | ||||||||||||||||||||||||||||||||||||||||||||||||||||

| SKU | FMINT32 | CTS-IT-349 | BBTMT002 | CTS-HW-360 | CTS-HX-009 | CTS-20T-GR-DF | ||||||||||||||||||||||||||||||||||||||||||||||||||||

| Rating | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Price | د.إ3,980.00 | د.إ1,300.00 | د.إ500.00 | د.إ1,380.00 | د.إ2,200.00 | د.إ4,210.00 | ||||||||||||||||||||||||||||||||||||||||||||||||||||

| Stock | In Stock

| In Stock

| In Stock

| In Stock

| In Stock

| In Stock

| ||||||||||||||||||||||||||||||||||||||||||||||||||||

| Availability | In Stock | In Stock | In Stock | In Stock | In Stock | In Stock | ||||||||||||||||||||||||||||||||||||||||||||||||||||

| Add to cart | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Description | Upon placing the order, we will get in touch with you to confirm the availability information. For Instant Enquiry and More Details, Please Click Here | Upon placing the order, we will get in touch with you to confirm the availability information. For Instant Enquiry and More Details, Please Click Here | This product will be in stock and available for purchase. | Upon placing the order, we will get in touch with you to confirm the availability information. For Instant Enquiry and More Details, Please Click Here | Upon placing the order, we will get in touch with you to confirm the availability information. For Instant Enquiry and More Details, Please Click Here | Upon placing the order, we will get in touch with you to confirm the availability information. For Instant Enquiry and More Details, Please Click Here | ||||||||||||||||||||||||||||||||||||||||||||||||||||

| Content | Highlights:

This part will replace the following OEM parts: 5Q0145803H, 5Q0145803K, 5Q0145803L, 5Q0145803P, 5Q0145803S, 5Q0145803N

Following on from our previous intercooler solution for the MK7 golf and MQB chassis variants that utilise the EA888 2.0 GEN3 2.0 TSI engine, we have designed our race intercooler to further enhance performance over the original intercooler and our previous iteration of our cooling solution, designed, developed and tested, at our headquarters in Gloucester UK. Throughout the development process we have strived to improve the efficiency and performance of the EA888 GEN3 engine. Our project brief was to develop an intercooler that utilised all of the available space in the original position of the OEM intercooler along with increasing the size again over our hugely successful product FMMK7FMIC. We also had to ensure the inlet air temperature is reduced, without any negative effects on the boost pressure or engine and transmission cooling.

In the MQB chassis the intercooler housing is particularly restricted and confined to a small amount of space, due to it not only housing the intercooler, but also the radiator and air conditioning condenser. The front panel in theory is a sandwich pack that houses the auxiliary cooling components. This means in order to increase the size of the intercooler without paying detriment to the performance of the surrounding items, and with also having very little extra space available, that it can be very difficult to execute the perfect blend of a high flow intercooler within such a close proximity. Our research and development engineers went back to the drawing board looking at previous documented dimensions while also taking new scans of the intercooler housing, this enabled the team to squeeze a further 10mm in depth of the core that houses very snugly into the earlier MQBs platform.

This part will replace the following OEM parts: 5Q0145803H, 5Q0145803K, 5Q0145803L, 5Q0145803P, 5Q0145803S, 5Q0145803N

Following on from our previous intercooler solution for the MK7 golf and MQB chassis variants that utilise the EA888 2.0 GEN3 2.0 TSI engine, we have designed our race intercooler to further enhance performance over the original intercooler and our previous iteration of our cooling solution, designed, developed and tested, at our headquarters in Gloucester UK. Throughout the development process we have strived to improve the efficiency and performance of the EA888 GEN3 engine. Our project brief was to develop an intercooler that utilised all of the available space in the original position of the OEM intercooler along with increasing the size again over our hugely successful product FMMK7FMIC. We also had to ensure the inlet air temperature is reduced, without any negative effects on the boost pressure or engine and transmission cooling.

In the MQB chassis the intercooler housing is particularly restricted and confined to a small amount of space, due to it not only housing the intercooler, but also the radiator and air conditioning condenser. The front panel in theory is a sandwich pack that houses the auxiliary cooling components. This means in order to increase the size of the intercooler without paying detriment to the performance of the surrounding items, and with also having very little extra space available, that it can be very difficult to execute the perfect blend of a high flow intercooler within such a close proximity. Our research and development engineers went back to the drawing board looking at previous documented dimensions while also taking new scans of the intercooler housing, this enabled the team to squeeze a further 10mm in depth of the core that houses very snugly into the earlier MQBs platform.

Why do we test different cores?Here at Forge Motorsport, when developing an intercooler, we will test several different cores for each application. For example, a bar and plate style core, a tube and fin style core along with different fin pitches and heights i.e. 22 fins per inch or 17 fins per inch as well as changing the internal fin pitches/shapes and density within the tube enabling to fine tune the amount of pressure drop the intercooler produces. Pressure drop is not always a bad thing, as our testing and research has proven on various projects, this is because the pressurized air velocity is being stalled by the pressure drop within the cooler thus allowing more time to cool the air within the cooler itself, as air passes through the non-pressurized face of the core, that is open to the atmosphere. Too much pressure drop can of course have a problem on the higher performance engines as the intercooler reaches its maximum efficiency the turbo has to work a lot harder to force the air through the core. This in turn creates higher inlet air temps (IAT’s) due to the turbo creating more heat as it is over stressed and worked harder. No pressure drop can also prove to be inefficient as the cooler will not lower the charge temperature again resulting in higher inlet air temperatures.

Dyno ResultsTesting was completed using Performance Remap in Gloucester with their VTEC 4-wheel drive dynamometer; this was to ensure all our data has been achieved with results as accurately as possible by an independent tuner. Peak power was increased from stock by 16bhp and 20nm of torque at 5500RPM with the Forge Motorsport performance intercooler installed. The best news is that there are significant torque gains throughout the rev range, meaning that the car power will pick up quicker and pull the whole way through to redline, including an impressive gain in BHP increase from 5000 RPM TO 6500 RPM. Gains on vehicles with re calibrated software and further hardware performance parts can be expected to be a lot higher due to the substantial drop in IATS when FMINT32 is installed.

Why do we try to reduce IAT's (Inlet Air Temperatures)?Temperature and volume of air supplied to your vehicles engine that is compressed by the turbo charger has a better effect on performance when cool as this is to provide the engine with more oxygen (denser air), thus improving the combustion in each cylinder. In addition, by regulating and reducing the air temperature, it also increases the reliability of an engine by keeping the AFRs (Air Fuel Ratios) in each cylinder at a safe level, which in turn, can increase an engines power due to the air being cooler. A bigger bang is then created within the cylinder, providing the correct amount of fuel is added. This can equate to an increase in BHP and torque.

Compatible Vehicles : | CTS Turbo is proud to announce the release of the high-flow aluminum charge pipe for new generations of B58C engines in G-series BMW 3.0T engines and A90 Toyota Supra 3.0T

The CTS Charge Pipe Kit offers more air flow than a factory pipe, OE-like fitment and peace of mind at any boost level. Our charge pipe kit will also improve the reliability of your B58C engine over the plastic stock part.

You’ll notice an increase in throttle response and a decrease in turbo lag. It’s is a must for vehicles tuned to run higher than stock boost level.

Product Details:

| BlackBoost Performance Engineering - Racing Coolant Thermostat. With our BlackBoost Racing Coolant Thermostat the coolant circulation with the radiator is always at 100% open. The factory coolant thermostat opens at 100°C / 212°F. Only for racing application, not recommended be used under very cold weather conditions. Applicable for: all M157 / M278 engines | CTS Turbo is proud to announce our Cast Aluminum 4″ turbo inlet for 8V Audi RS3/8S Audi TT-RS

The biggest issue with the restrictive factory inlet is apparent when you start to increase the power. Our engineers designed the turbo inlet to be as large as possible; yet still fit perfectly. This was accomplished using the latest in 3D scanning and rapid prototyping technology. This results in a 78% increase in volume over the stock turbo inlet.

The larger inlet will provide increased flow to the turbo and make sure your 2.5T has all the air that it needs to operate at maximum capacity! This is one of the largest inlet pipes on the market AND it does not cost you a small fortune.

Features:

Model Generation:AUDI RS3 2018 - 2020 8VAUDITags TTRS 2017 - 2020 8S | CTS Turbo is excited to introduce our upgraded Aluminum heat exchanger specifically designed for the B9 Audi RS5. We understand that the factory heat exchanger falls short in effectively cooling tuned engines, which is why we developed our own solution.

Our heat exchanger boasts a significantly larger volume than OEM, featuring a dual-pass core that seamlessly complements the factory heat exchanger with minimal modifications required for installation. Ensure optimal cooling and dependable performance for your 2.9T V6 twin-turbo engine with the CTS Turbo Aluminum heat exchanger.

Features:

| The CTS MK6 2.0T Direct Fit FMIC Kit is designed as a drop in replacement for the OEM front mounted intercooler (FMIC). That means you can install this kit without any trimming or modification of the bumper. The OEM FMIC is adequate for stock boost levels, however once boost levels are increased by way of ECU upgrades/chipping the OEM FMIC struggles to keep the charged air temperatures in check. Higher charged air temperatures can result in boost cut and timing pull, both reducing the amount of power your vehicle produces.

The CTS direct fit FMIC uses a high efficiency bar and plate intercooler core, which aids in reducing pressure drop. Reducing pressure drop means that your turbo will not have to work as hard to make a given level of boost. If your turbo makes 30psi of boost pressure in the turbocharger, and your intercooler has a 10psi pressure drop then the boost measured by your ECU would be (30psi – 10psi) = 20psi. With an efficient FMIC like the CTS direct fit FMIC your turbo does not have to work as hard to reach desired boost levels. This is beneficial in two ways, the turbo life expectancy is increased due to more efficient operation, and boost leaving the turbocharger is cooler and more dense resulting in more power to the ground.

Product Details:

– Efficient bar and plate construction

– Direct bolt-in installation

– 4-ply silicon hoses and billet adapter to turbo outlet pipe

– High quality stainless steel clamps

– Low pressure drop

– Maintains factory mounting points

– No trimming of bumper or crash supports

– Rated for power levels in excess of 600HP

– Core dimensions: 23.00 Length x 2.00″ Tall x 16.5″ Height

– Cast aluminium end tanks with mounting points that are CAST into the end tank, NOT welded like inferior intercoolers

Fitment:

2012-2013 VW Golf R 2.0T

| ||||||||||||||||||||||||||||||||||||||||||||||||||||

| Weight | N/A | N/A | N/A | N/A | N/A | N/A | ||||||||||||||||||||||||||||||||||||||||||||||||||||

| Dimensions | N/A | N/A | N/A | N/A | N/A | N/A | ||||||||||||||||||||||||||||||||||||||||||||||||||||

| Additional information |

|

|

|

|

|

|

Reviews

There are no reviews yet.